Greening the Industry – Azerbaijani textile manufacturers Alyans, Baku, and BETEX benefit from taking part in the EU4Environment company assessments

Worldwide, the textile market is valued at around 1,000 billion EUR, with a growth rate of 4% per year. This makes the apparel and textile sectors the fourth biggest in the world; which, in turn, allows them to enjoy a labour force of more than 300 million workers and a strong influence in the development of the economy, society, and environment, overall.

Fast fashion has also become widely promoted, mostly online, through e-commerce platforms and retail companies. With the rise of fast fashion, clothing, in general, has become cheaper, fast-changing (to keep up with trends), and easy to purchase. However, such achievements have often been made at the expense of the environment and workers’ health. As products are often of low quality, workers are being underpaid (due to the low cost of garment production) or overworked, and many textile items end up in landfill after short use. Textile production typically requires large quantities of water, energy, and chemicals to produce fibres, fabrics, and non-wovens. Hence, the textile industry has become responsible for 20% of the pollution of all rivers and lands, and for generating.

To create new garments, chemicals are used in production and packaging, as well as large quantities of water (2,700 litres of water are needed to produce a single t-shirt). In addition to the consumption of water, chemicals and energy (for the production of materials and their finishing), the high consumption of energy (in production and transport) with its subsequent release of greenhouse gases, are all added to the environmental impact of the industry. These challenges thus need to be addressed in a sustainable and holistic way. Initiatives such as the UN Alliance for Sustainable Fashion and the EU Strategy for Sustainable Textiles are designed to promote projects and policies targeting the fashion value chains that contribute towards the achievement of the SDGs. On top of that, at the company level, manufacturers can learn to embrace approaches embedded in resource efficiency and shift their linear production processes towards circular and even net-zero ones. But what is the process of creating a garment?

Raw materials are needed to create fabrics for garments; these can be either harvested from plants (cotton, flax) and animals (silk, wool) or created synthetically (nylon, polyester). The manufacturing process is then split into three distinct processes: the raw fibres are spun into yarn and threads, then weaved from individual pieces into a fabric (greige), and finally, the fabric is processed (here, pre-treatment processes can be carried out to prepare the fabric for dyes and functional chemicals) from which it is ready for distribution. While garments are the most popular textile products, fabrics are also used in household items, upholstery, and many other products.

The textile industry in Azerbaijan

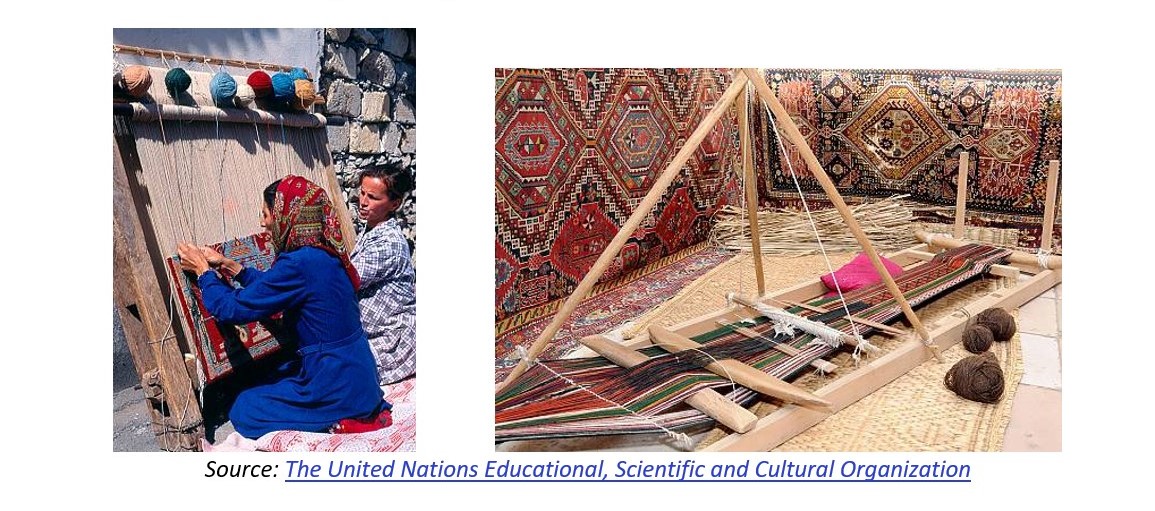

Azerbaijan has a long tradition in the production of yarn, clothes, carpets, leather, and shoes. The processing of silk and wool has become intrinsically linked to society and certain items have now become intangible cultural heritages. This is the case of the traditional art and symbolism of Kelaghayi (the creation of women’s silk headscarves) and the traditional carpet weaving which are now part of the UNESCO list for intangible heritages.

Presently, the country invests in modernizing its garment production, with initiatives such as the "State Program for the Development of Cotton Growing in the period 2017 to 2022" aiming to guide industries further. In 2019, the retail value of yarn items, apparel, and footwear reached over 1.5 billion EUR, with Baku Textiles LLC being one of the biggest names in Azerbaijan’s textile industry (with a production of over 5,000 different varieties of textile products). In the same year, the country exported textile fabrics worth 2.2 million EUR into the European Union, out of which most have been worn clothing (79%), followed by articles of apparel and clothing accessories (not knitted and crocheted) (10%), cotton (6%), and carpets and coverings (1%). Most Azerbaijani manufacturers are represented by Small and Medium-sized Enterprises (SMEs), located around Baku and in other major cities. This is also the case of three Azerbaijani textile manufacturers which have joined the UNIDO Resource Efficient and Cleaner Production (RECP) Demonstration Project under the EU4Environment Action:

Alyans Textile LLC

Located in Sumgayit city, “Alliance Textile” LLC is a producer of workwear and special wear (overalls, suits, jackets, etc.), as well as a wholesaler of safety footwear and all kind of Personal Protective Equipment (PPE): respirators, helmets, gloves, ear plugs, and many more. With 134 employees, Alyans handles everything from textile design all the way to shelf-ready products. During the RECP monitoring visits, the interest of the company has been to identify ways to improve its overall production (including in terms of energy efficiency and waste management).

Baku Textile LLC

Baku Textile LLC is a company situated in Azerbaijan’s capital city, having 147 employees and being specialized in the production of uniforms, socks, and working clothes (according to orders coming directly from their customers). In addition to using the latest raw materials and available technologies, the company also enjoys the presence of foreign experts who bring modern expertise to the production line. Presently, it produces more than 5,000 different types of textiles of high quality, as well as a variety of products destined for government and national service companies. Concerned with its environmental performance, Baku Textile LLC was interested to join the UNIDO RECP Demonstration Project to reduce its waste and energy consumption.

BETEX Textile LLC

BETEX Textile LLC is a textile manufacturer operating in Sumgayit Chemical Industrial Park. Established in December 2020, it works with modern equipment and facilities. The company specialises in the production of trousers, shirts, robes, and other clothing items. With 18 employees, the company handles both domestic and international orders (mainly from Turkey). Depending on the volume of the orders, workers from Baku Textile LLC come to BETEX Textile to collaborate on the production line. In the past, the company also produced medical masks. Currently, it aims to take advantage of the RECP Demonstration Project to reduce waste, improve energy savings, and boost energy production from renewable sources through the installation of solar panels.

Motivated to improve their production and take an active lead in promoting circular economy practices in the context of the textile value chain, Alyans Textile LLC, Baku Textile LLC, and BETEX Textile LLC have all joined the UNIDO RECP Project under EU4Environment as Demonstration Companies. During several visits performed in 2021 and 2022 by the RECP project team, existing gaps and opportunities to improve resource usage and minimise waste have been identified. These were based on data analysis and calculations to assess ongoing inefficiencies. Once the RECP team finalises the resource efficiency reports for each company, the findings will help these textile producers reduce their negative environmental impact and improve their efficiency and competitive edge, all while taking an active role in promoting a circular and sustainable means of production in the textile industry.