RECP

Resource Efficient and Cleaner Production (RECP) represents the continuous application of preventive environmental strategies to processes, products, and services to increase efficiency and reduce risks to humans and the environment. RECP addresses the three sustainability dimensions individually and synergistically:

a) heightened economic performance through improved productive use of resources

b) environmental protection by conserving resources and minimizing the industries’ impact on the natural environment

c) social enhancement by providing jobs and protecting the wellbeing of workers and local communities.

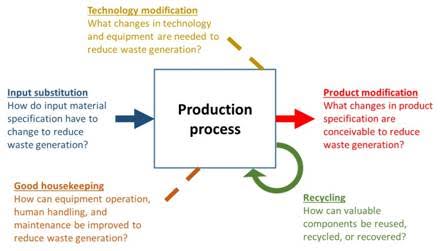

Several complementary RECP techniques or practices are possible, ranging from low or even no cost solutions to high investment, advanced clean technologies, including:

Good Housekeeping: Changes in operational procedures and management in order to eliminate waste and emissions generation. Examples are spill prevention, improved instruction, and the training of site personnel;

Input Material Change: The use of less polluting raw materials and the use of process auxiliaries (such as lubricants and coolants) with a long service lifetime;

Technology Change: For example, improved process automation, process optimization, equipment redesign, and process substitution;

Recycling: The useful application or reuse of waste materials at the same company at which they were generated, and recycling outside of the company;

Product Modification: Change of the characteristics of the product, such as material composition and shape. This way, the life time of the new product could be extended, the product, made easier to repair, or the manufacturing of the project could become less polluting. The changes in product packaging are generally also regarded as product modifications.

For more information on this topic, please visit the UNIDO designated webpage on RECP